The Ultimate Guide to Measuring Machines: Precision and Efficiency in Modern Manufacturing

In today's fast-paced and highly competitive manufacturing industry, precision and accuracy are more critical than ever. Whether you're involved in automotive production, aerospace engineering, or any other field that requires meticulous attention to detail, measuring machines have become indispensable tools. These machines ensure that every component produced meets exact specifications, reducing waste and increasing overall efficiency.

In this blog, we'll explore what measuring machines are, their types, applications, and how they contribute to the modern manufacturing process.

What Are Measuring Machines?

Measuring machines, also known as coordinate measuring machines (CMMs), are devices used to measure the physical geometrical characteristics of an object. They use a probe to detect the object's surface and create precise measurements, which are essential in quality control and assurance processes. These machines can measure objects in three dimensions (X, Y, and Z axes), allowing manufacturers to verify that a part meets design specifications.

Types of Measuring Machines

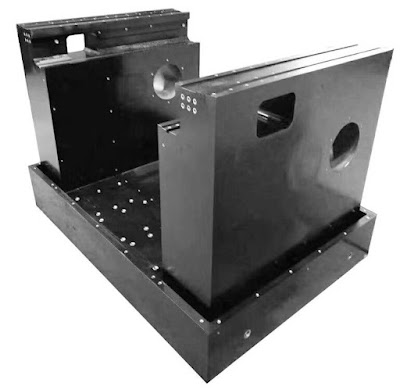

Coordinate Measuring Machines (CMMs):

- Bridge CMMs: The most common type, featuring a movable bridge that holds the probe and moves along the X and Y axes.

- Gantry CMMs: Ideal for large parts, with the measuring head moving across a fixed table.

- Cantilever CMMs: A single-arm design that allows for easy access to the measuring area, typically used for smaller parts.

- Portable CMMs: Lightweight and versatile, suitable for on-site measurements.

Vision Measuring Machines: These machines use optical systems, such as cameras and lasers, to capture the dimensions of a part without physical contact. They are perfect for delicate or soft materials where traditional probing might cause damage.

Laser Trackers: A highly precise measurement tool that uses laser technology to track the position of a reflective target. Laser trackers are commonly used in large-scale applications such as aircraft assembly.

3D Scanners: These devices capture the entire surface of an object by creating a digital model, which can then be analyzed for precise measurements. 3D scanners are widely used in reverse engineering and quality control.

Applications of Measuring Machines

Measuring machines are used across various industries, each with unique requirements:

- Automotive Industry: Ensuring that every component, from engine parts to body panels, meets tight tolerances for safety and performance.

- Aerospace Industry: Providing the precision needed to manufacture complex parts for aircraft and spacecraft, where even the smallest error can have significant consequences.

- Medical Device Manufacturing: Ensuring that medical devices meet strict regulatory standards for safety and effectiveness.

- Electronics: Measuring tiny components with high precision, essential for the functionality of electronic devices.

How Measuring Machines Enhance Manufacturing Efficiency

Accuracy: Measuring machines provide unparalleled accuracy, ensuring that every part produced meets design specifications. This reduces the risk of defects and rework, saving time and money.

Speed: With automated measuring processes, manufacturers can quickly verify the dimensions of a part, allowing for faster production cycles and shorter lead times.

Versatility: Whether dealing with small, delicate components or large, complex assemblies, measuring machines can handle a wide range of parts, making them a versatile tool in any manufacturing environment.

Data Collection and Analysis: Modern measuring machines often come with software that allows for detailed data collection and analysis. This data can be used to improve manufacturing processes, reduce waste, and increase overall efficiency.

Choosing the Right Measuring Machine for Your Needs

Selecting the right measuring machine depends on several factors, including the size and complexity of the parts you need to measure, the level of accuracy required, and your budget. Here are some tips to help you make the right choice:

Consider the Material: Different materials may require different types of measurement techniques. For example, delicate materials might benefit from non-contact methods like vision measuring machines or 3D scanners.

Evaluate Your Production Volume: High-volume production might require faster measuring machines with automation capabilities to keep up with the demand.

Think About Future Needs: As your business grows, your measurement needs may change. Investing in a versatile machine that can handle various tasks might save you from needing to upgrade later.

Conclusion

Measuring machines are a vital component of modern manufacturing, offering the precision, efficiency, and versatility needed to produce high-quality products. Whether you're in automotive, aerospace, medical devices, or electronics, investing in the right measuring machine can enhance your manufacturing process, reduce waste, and improve overall quality.

By understanding the different types of measuring machines and their applications, you can make an informed decision that aligns with your specific needs and goals. With the right tools, you can ensure that every part you produce meets the highest standards, helping your business stay competitive in an ever-evolving industry.

Comments

Post a Comment