Understanding the Role of the Machine Bed in Manufacturing: A Comprehensive Guide

In the world of manufacturing, precision and stability are crucial for producing high-quality parts. Whether it's a CNC machine, lathe, or milling system, one often overlooked but essential component is the machine bed. Acting as the backbone of the entire machine structure, the machine bed plays a vital role in ensuring accuracy, stability, and longevity in the manufacturing process.

What is a Machine Bed?

A machine bed is the foundational structure on which all other components of a machine are mounted. It serves as the primary support for various machine elements such as spindles, tool holders, motors, and workpieces. Constructed from high-strength materials like cast iron or steel, it provides a stable and vibration-resistant surface that allows the machine to perform accurate operations over long periods of time.

Key Functions of the Machine Bed

Stability and Rigidity: The primary function of a machine bed is to provide rigidity and stability. Machines like CNC mills and lathes require a stable base to ensure precise cutting and shaping. Any instability in the machine bed can lead to vibrations that reduce accuracy and damage the tool or workpiece. A well-constructed machine bed prevents these issues, allowing for smooth and controlled operations.

Vibration Dampening: During high-speed machining, vibrations are inevitable, especially when working with hard materials. Excessive vibrations can cause tool wear and reduce the quality of the finished product. A machine bed, due to its mass and material composition, acts as a natural damper for these vibrations, minimizing their impact on the machine’s performance.

Support for Moving Parts: Many machines, such as CNC routers and mills, involve moving components like spindles, tool carriages, or cutting heads. The machine bed provides a flat and level surface, ensuring that these moving parts remain aligned during operation. This is essential for maintaining precision, especially in multi-axis machines where even slight deviations can result in costly errors.

Load Bearing: The machine bed also supports the weight of both the machine components and the workpieces being processed. It’s designed to handle heavy loads without bending or deforming. This load-bearing capacity is crucial when working with large or heavy materials, ensuring that the machine operates effectively without compromising on accuracy.

Thermal Stability: In some high-precision machines, thermal expansion can become an issue. Changes in temperature can cause machine components to expand or contract, potentially leading to inaccuracies in machining. High-quality machine beds are often designed to be thermally stable, resisting expansion or contraction even in varying temperatures.

Types of Machine Beds

Machine beds come in different shapes and sizes depending on the type of machine and its intended application. Some common types include:

Flat Bed: Typically used in lathes, flat machine beds provide a smooth surface for tool movements along the X and Z axes. This design is simple yet effective for machining cylindrical components.

Slant Bed: In slant bed lathes, the bed is angled to improve chip evacuation and reduce the effects of gravity on the cutting tool. This design enhances the ergonomics of the machine and improves the overall precision of machining.

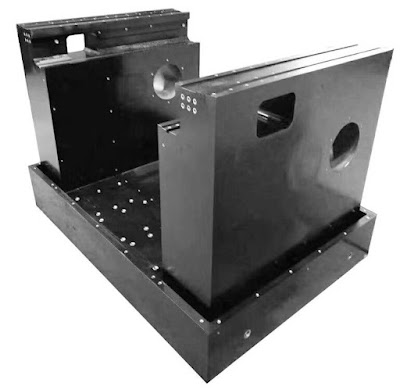

Box Bed: Found in heavy-duty milling and boring machines, box beds are designed to handle large and heavy workpieces. They are robust and provide superior stability, especially in machines where large tools are used to remove a significant amount of material.

Gantry Bed: In CNC routers and plasma cutting machines, gantry beds provide support for a moving bridge (gantry) that carries the cutting tools. These beds need to be large and rigid, especially when processing sheet materials like wood, plastic, or metal.

Materials Used in Machine Beds

Machine beds are typically made from materials that provide strength, rigidity, and vibration dampening. The most common materials include:

Cast Iron: Known for its excellent vibration-dampening properties, cast iron is the most common material used in machine beds. Its high density makes it ideal for absorbing vibrations and providing a stable base for machining operations.

Steel: Steel beds are stronger and more resistant to wear compared to cast iron. However, steel does not have the same vibration-dampening properties, so it is often used in conjunction with other materials or designs to counteract this.

Granite or Polymer Composite: In high-precision applications, materials like granite or polymer composites are used for their superior thermal stability and vibration absorption. These materials are typically found in ultra-precision machines where even the smallest vibration can affect the quality of the finished product.

Maintenance and Care of Machine Beds

Maintaining the integrity of a machine bed is critical for ensuring the longevity and performance of the machine. Here are a few maintenance tips:

Regular Cleaning: Machine beds should be kept clean from chips, debris, and lubricants that accumulate during operation. This prevents wear and tear on the surface and ensures the smooth movement of machine components.

Lubrication: Moving parts like guideways that interact with the machine bed should be properly lubricated to reduce friction and wear.

Inspection: Regularly inspect the machine bed for any signs of wear, cracks, or deformities. Early detection of issues can prevent costly repairs or downtime.

Leveling: Over time, machine beds can become unlevel due to vibrations and usage. It’s important to check the level of the machine periodically and make adjustments as needed.

Conclusion

The machine bed is often referred to as the "heart" of a machine tool due to its critical role in maintaining precision and stability. Without a properly designed and maintained bed, even the most advanced machines can fall short in delivering high-quality results. Whether you're working with a CNC machine, lathe, or milling setup, understanding the importance of the machine bed is key to ensuring the success of any manufacturing process. Investing in a high-quality machine bed and maintaining it well can dramatically improve the performance and longevity of your machinery.

Comments

Post a Comment