The Evolution of Machine Bed Materials: Enhancing Precision and Performance in Modern Machinery

- Get link

- X

- Other Apps

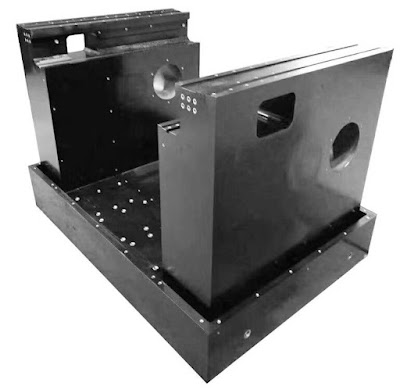

In the world of precision engineering and manufacturing, the machine bed, often referred to as the machine base, plays a crucial role in ensuring the stability, accuracy, and longevity of various machines, from CNC milling machines to large-scale industrial equipment. The materials used for constructing machine beds have evolved significantly over the years, driven by advancements in technology, the need for higher precision, and demands for more durable and stable bases. This blog delves into the different materials used in machine bed construction, highlighting their advantages and applications.

Traditional Materials: Cast Iron and Steel

Cast Iron

For many decades, cast iron has been the material of choice for machine beds. Its popularity stems from its excellent damping properties, which help in absorbing vibrations during machine operations. This characteristic is vital for maintaining precision in machining processes.

Advantages of Cast Iron:

- High Damping Capacity: Reduces vibrations and enhances machining accuracy.

- Durability: Long-lasting and resistant to wear and tear.

- Cost-Effective: Relatively low cost of production.

However, cast iron also has some limitations. It is relatively heavy, which can be a disadvantage in applications requiring mobility. Additionally, its brittleness can lead to cracking under extreme conditions.

Steel

Steel has also been a common material for machine beds, particularly in applications requiring higher strength and toughness compared to cast iron. Steel beds can be welded, allowing for more complex shapes and designs.

Advantages of Steel:

- High Strength and Toughness: Suitable for heavy-duty applications.

- Weldability: Allows for the creation of intricate shapes.

- Ductility: Less prone to cracking compared to cast iron.

Despite these benefits, steel does not offer the same level of vibration damping as cast iron, which can be a drawback in high-precision machining.

Modern Materials: Polymer Concrete and Composite Materials

Polymer Concrete

In recent years, polymer concrete has gained popularity as a material for machine beds, particularly in high-precision applications. This material is a mixture of resin and aggregates, which can include quartz, granite, or other materials.

Advantages of Polymer Concrete:

- Exceptional Vibration Damping: Superior to both cast iron and steel.

- Thermal Stability: Resistant to temperature fluctuations, maintaining precision.

- Customizability: Can be molded into complex shapes.

Polymer concrete is more expensive than traditional materials, but its benefits in precision and stability often justify the cost in high-end applications.

Composite Materials

Composite materials, which combine different substances to exploit their individual strengths, are also being used for machine beds. These can include combinations of metals, ceramics, and polymers.

Advantages of Composite Materials:

- Lightweight: Easier to handle and move compared to traditional materials.

- Tailored Properties: Material properties can be customized for specific applications.

- Enhanced Performance: Can offer a combination of high strength, good damping, and thermal stability.

The complexity and cost of producing composite materials can be higher, but the performance benefits are significant, particularly in advanced and specialized machinery.

Future Trends: Additive Manufacturing and Advanced Alloys

As technology continues to advance, new materials and manufacturing techniques are emerging that could revolutionize machine bed construction. Additive manufacturing (3D printing) is one such technology, allowing for the creation of highly complex and optimized structures that are not possible with traditional methods. Advanced alloys and new composite materials are also being developed to provide even better performance in terms of strength, damping, and thermal stability.

Potential Benefits of Future Materials:

- Optimized Designs: More efficient and effective machine bed structures.

- Enhanced Precision: Better control over material properties for higher precision.

- Sustainability: Potential for using more eco-friendly materials and processes.

Conclusion

The choice of material for a machine bed is critical to the performance, accuracy, and durability of machinery. From traditional cast iron and steel to modern polymer concrete and composites, the evolution of machine bed materials reflects ongoing advancements in technology and engineering. As we look to the future, new materials and manufacturing techniques promise to further enhance the capabilities of machines, driving innovation and efficiency in various industries.

Understanding the properties and applications of different machine bed materials allows manufacturers to make informed decisions, ensuring that their machinery meets the demands of modern precision engineering and industrial requirements.

- Get link

- X

- Other Apps

Comments

Post a Comment