The Importance of Selecting The Right Machine Bed Supplier

When it comes to the manufacturing industry, one of the key components that can significantly influence the quality and precision of production is the machine bed. As the foundation of heavy machinery, the machine bed ensures stability, accuracy, and longevity. In this blog post, we'll explore the importance of selecting the right machine bed supplier, the qualities to look for in a supplier, and how to make an informed decision.

Why the Right Machine Bed Matters

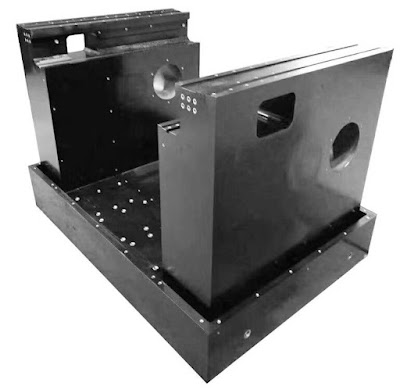

A machine bed is the base structure of many types of machinery, such as CNC machines, lathes, and milling machines. It supports the entire machine and absorbs vibrations, ensuring smooth and accurate operations. The quality of the machine bed directly affects the performance and lifespan of the machinery.

Key Functions of a Machine Bed:

- Stability: Provides a stable foundation, reducing vibrations and ensuring precise operations.

- Support: Supports all components of the machinery, maintaining alignment and accuracy.

- Durability: Built to withstand heavy loads and harsh conditions, ensuring long-term performance.

Given its crucial role, choosing the right machine bed supplier is essential for maintaining high standards in your manufacturing processes.

Qualities to Look for in a Machine Bed Supplier

When searching for a reliable machine bed supplier, several factors should be considered to ensure you receive high-quality products and excellent service.

1. Quality of Materials

The materials used in constructing machine beds significantly impact their performance and durability. Look for suppliers who use high-grade materials such as cast iron, steel, or composites known for their strength and resistance to wear and tear.

Tip: Ask for detailed specifications and material certifications to verify the quality.

2. Precision Engineering

The precision with which a machine bed is manufactured determines the accuracy of the machinery it supports. Ensure the supplier uses advanced manufacturing techniques and adheres to strict quality control standards.

Tip: Visit the supplier’s manufacturing facility if possible, to observe their production processes and quality control measures.

3. Customization Options

Different manufacturing processes require specific machine bed configurations. A good supplier should offer customization options to meet your unique needs.

Tip: Discuss your specific requirements with the supplier and see if they can provide tailored solutions.

4. Reputation and Experience

A supplier’s reputation and experience in the industry can be a strong indicator of their reliability and the quality of their products.

Tip: Look for reviews, testimonials, and case studies from previous clients. Long-standing suppliers with a positive track record are often more dependable.

5. Technical Support and Service

Technical support and after-sales service are crucial, especially when dealing with complex machinery. Choose a supplier who offers comprehensive support, including installation, maintenance, and troubleshooting.

Tip: Inquire about the supplier’s service policies and response times. Good support can save you significant time and money in the long run.

6. Competitive Pricing

While quality should never be compromised, it’s essential to find a supplier who offers competitive pricing. Ensure you get value for your money by comparing quotes from different suppliers.

Tip: Consider the total cost of ownership, including the initial purchase price, maintenance costs, and potential downtime costs.

Making an Informed Decision

To make an informed decision when choosing a machine bed supplier, follow these steps:

- Research: Gather information on potential suppliers, including their products, services, and reputation.

- Evaluate: Assess suppliers based on the qualities mentioned above, such as material quality, precision engineering, and customer support.

- Request Quotes: Obtain detailed quotes from shortlisted suppliers, including customization options and after-sales service.

- Visit Facilities: If possible, visit the manufacturing facilities of potential suppliers to observe their processes and quality control measures.

- Check References: Contact previous clients or read reviews to gauge the supplier’s reliability and product quality.

- Make a Decision: Choose the supplier that best meets your needs in terms of quality, customization, support, and pricing.

Conclusion

Choosing the right machine bed supplier is a critical decision that can impact the efficiency, accuracy, and longevity of your manufacturing operations. By considering factors such as material quality, precision engineering, customization options, reputation, and support services, you can make an informed choice that will benefit your business in the long run.

Comments

Post a Comment