The Backbone of Precision: Understanding Machine Tool Beds

In the world of manufacturing and machining, the machine tool bed serves as the foundational element that ensures accuracy, stability, and performance. As a critical component in various machine tools, the bed plays a vital role in the overall efficiency and effectiveness of machining operations. In this blog, we’ll explore what a machine tool bed is, its types, materials, design considerations, and its impact on machining processes.

What is a Machine Tool Bed?

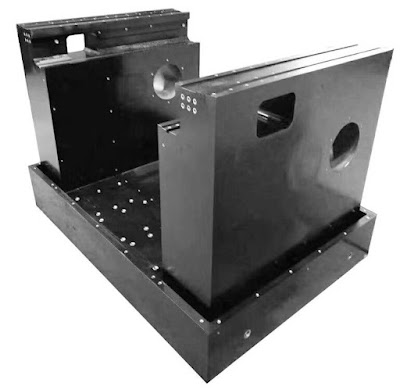

A machine tool bed is the base structure that supports the machine components, including the spindle, motor, and other essential parts. It provides a stable platform for the entire machine, ensuring that all movements are precise and consistent. The bed must be rigid enough to withstand the forces generated during machining while also being designed to minimize vibrations, which can affect the quality of the finished product.

Types of Machine Tool Beds

Cast Iron Beds: One of the most common materials used for machine tool beds, cast iron provides excellent vibration-dampening properties and rigidity. It is often used in lathes, milling machines, and other heavy-duty machinery.

Steel Beds: While lighter than cast iron, steel beds offer high strength and durability. They are often used in lighter machines or where portability is a concern.

Granite Beds: Used primarily in precision machining applications, granite beds provide exceptional stability and vibration dampening, making them ideal for high-precision tasks.

Composite Beds: Some modern machines utilize composite materials to achieve a balance of weight, strength, and vibration dampening. These beds are becoming increasingly popular in advanced machining centers.

Key Design Considerations

Rigidity: The bed must be designed to withstand significant forces without deforming, ensuring consistent machining results.

Vibration Control: A well-designed bed should minimize vibrations, which can lead to inaccuracies in machining. The choice of material plays a crucial role in this aspect.

Thermal Stability: Temperature changes can affect the dimensions of the machine and the workpiece. A good machine tool bed should have minimal thermal expansion characteristics to maintain accuracy.

Weight: While heavier beds generally provide more stability, they can also make machines less portable. Designers must strike a balance between weight and performance based on the intended use.

Surface Finish: The bed's surface should be finished to facilitate the smooth movement of other components, such as slides and tables, and to ensure proper alignment.

Impact on Machining Processes

The quality and design of the machine tool bed have a direct impact on the machining process. A well-constructed bed enhances the overall accuracy of the machine, leading to:

Improved Precision: With a stable foundation, tools can operate more accurately, producing parts that meet tight tolerances.

Reduced Wear: A rigid bed minimizes unnecessary movement and vibrations, leading to less wear on the machine components and longer tool life.

Enhanced Productivity: Consistent machining performance allows for faster production rates and improved efficiency, ultimately benefiting the bottom line.

Conclusion

The machine tool bed is a critical component in the world of machining, serving as the backbone that supports precision and performance. By understanding the different types, materials, and design considerations of machine tool beds, manufacturers can make informed decisions that enhance their machining processes.

Investing in a high-quality machine tool bed not only improves the accuracy and reliability of machining operations but also contributes to the overall success and efficiency of manufacturing processes. As technology continues to advance, the importance of a robust and well-designed machine tool bed will only grow, solidifying its place as a vital element in modern machining.

Comments

Post a Comment